High Shear Mixers - Common Models

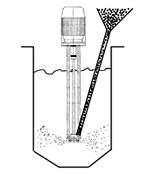

Batch High Shear Mixers

Available in standard and sanitary configurations to meet the exact needs of your process.

Our batch designs can be permanently mounted to the mix tank or suspended over the vessel using a portable or permanent lifting mechanism. When supplied with a portable/mobile lifting mechanism, you can enjoy the use of the mixer in multiple mix vessels and also in different areas of your manufacturing plant. Whether the lift is portable or fixed, you are able to vary the position of the agitator within the vessel, to fine-tune the process and to handle a wide variety of materials.

Rotor/Stator Mixers are generally applied on products that are up to approx. 10,000 cps. The four-blade rotor of the standard design, turns within a close tolerance stator at roughly 4,000 fpm. The higher energy units can rotate at speeds over 16,000 fpm and offer end results that are sometimes equal to or better than a conventional homogenizer. The rotor-stator mixer is great for applications that require fast particle size/droplet reduction. Homogenization, solids size reduction, emulsification, are perfect applications for this versatile mixer.

Standard Rotor-Stator mixers are available with a selection of stator heads to help fine-tune the mixer for your process.

Inline High Shear Mixers

Our Inline mixers are available in many designs ranging from our single stage rotor-stator mixers to those that include many concentric rows of close tolerance intermeshing teeth. This range of designs enables a user to select the exact model for his particular process demands.

Lab Inline |

Production Inline |

Sanitary Inline |

Single stage design - provides a cost efficient mixing solution for many applications. Available are four standard stator heads: round hole, square hole, slotted & fine screen. The single stage model is available in standard intermittent service design, and also a continuous duty design. All units are available with vessels and piping to allow for recirculation or continuous processing.

Round |

Slotted |  Square |  Fine Screen |

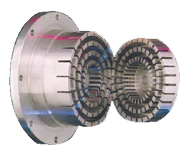

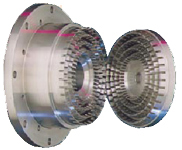

Multi-stage design - These include two or four rows of rotating blades that nest inside a matching stator. The mix material enters through an inlet connection and is accelerated outward by centrifugal force. During each transit through the rotor-stator, the material is subjected to a succession of increasingly intense shearing events -until it finally exits downstream, or is recirculated for another pass through the mixer. Uniform droplets below 1 micron are possible using these designs.

Special Ultra High Shear designs include

Low Profile X design - The X-Series rotor and stator is comprised of many concentric rows of intermeshing teeth. Tolerances are very close, and the shear rates are extremely high. This unit operates at tip speeds up to 18,000 fpm. The X is a great choice for emulsions and dispersions that would otherwise have required more expensive homogenizers or colloid mills.

MegaShear design - The MegaShear rotor and stator is of a unique design, consisting of opposed, semi-circular, cylindrical grooves that are machined on both the rotor and stator faces. When a fluid is exposed to these opposed partial cylinders, a counter-flow is induced which splits and redirects the flow of the fluid upon itself to create an extremely high-turbulent collision phenomenon.

Ultra High Shear

The high tip speeds and complex turbulent mixing patterns generated within the rotor/stator assembly of an ultra-high shear mixer enable it to produce fine emulsions and dispersions. The benefit of preparing a higher quality pre-mix lies in the reduction of passes through the high pressure homogenizer, an inherently low-throughput device. A greater volume of end product can therefore be produced per operating hour of the homogenizer. Being an inline device, the ultra-high shear mixer can mix raw materials and pump the mixture directly to the homogenizer. Flowrate is comparatively higher than a similarly powered homogenizer.

Technical Reports

1. Upgrade your colloid milling

operation ![]()

2. Ultra-high shear mixers increase overall throughput and efficiency of homogenization processes. ![]()

3. Ultra-high shear mixing of nanoparticles ![]()

4. Homogenization of submicron emulsions ![]()

5. New technologies for continuous mixing and homogenization of nano-filled materials ![]()

6. Ultra-high shear mixing and deagglomeration ![]()

Special Ultra High Shear designs include

Multi-stage design - These include two or four rows of rotating blades that nest inside a matching stator. The mix material enters through an inlet connection and is accelerated outward by centrifugal force. During each transit through the rotor-stator, the material is subjected to a succession of increasingly intense shearing events -until it finally exits downstream, or is recirculated for another pass through the mixer. Uniform droplets below 1 micron are possible using these designs.

Low Profile X design - The X-Series rotor and stator is comprised of many concentric rows of intermeshing teeth. Tolerances are very close, and the shear rates are extremely high. This unit operates at tip speeds up to 18,000 fpm. The X is a great choice for emulsions and dispersions that would otherwise have required more expensive homogenizers or colloid mills.

MegaShear design - The MegaShear rotor and stator is of a unique design, consisting of opposed, semi-circular, cylindrical grooves that are machined on both the rotor and stator faces. When a fluid is exposed to these opposed partial cylinders, a counter-flow is induced which splits and redirects the flow of the fluid upon itself to create an extremely high-turbulent collision phenomenon.

Dispersers

The Ross High Speed Disperser is built with all of the features and versatility required to produce a wide variety of products. This age old design has been refined and updated for longer life, improved performance and reduced maintenance costs.

Our Standard design includes features such as:

- Explosion proof inverter duty motors

- Heavy duty V-belt drives and bearings

- Stainless steel wetted parts

- Safety switches

- Adjustable mix can lock mechanism

- Air/oil hydraulic lift

High Speed Dispersers are ideal for dispersions that are up to a maximum of approx. 50,000 centipoise. When used in conjunction with Multi-Shaft Mixers, they can be used for products up to several hundred thousand centipoise. Dispersers are available from bench top sizes to very large production sizes capable of dispersing several thousand gallons at a time.

A few rules of thumb to consider when sizing a Single Shaft - High Speed Disperser

Viscosity – make sure the viscosity is such that it can be mixed using a single shaft mixer. The materials are usually within an upper viscosity range of 50,000 centipoise. The materials are ideally thixotropic (shear thinning) and flow well under shearing/mixing conditions

Volume – Determine the volume of product required to meet your production forecasts. Establish the optimum batch size to match your facilities and available personnel.

Vessel design – The optimum vessel design is one that is round with a dished bottom. This design promotes good flow and minimizes the possibility of dead spots where unmixed materials can collect. A flat or sloped bottom is also typical. In general, a vessel that is approximately the same diameter and height is preferred for use with dispersers. Please allow for vortexing of the product by having the sidewalls of the vessel at 30% (freeboard) above the full batch level when the product is at rest. The dispersion blade is normally positioned .5 of the blade diameter off of the vessel bottom. The vessel diameter should be 3x the blade diameter. The full batch level at rest should be 1.5 blade diameters above the blade.

Disperser size and speed – The blade diameter should be roughly 1/3rd the diameter of the vessel. Power consumption will be determined by the diameter of the blade, the density of the formulation, and the speed at which the blade turns. A typical disperser is sized in the range of 10 HP per 100 gallons of product to be mixed. Normal blade is speed is in the 4800 - 5200 fpm (feet per minute) range.

SLIM

Mixing Insight - SLIM Operates without Eductor

SLIM Eliminates Dust in Mixing Area

Optimize powder injection in your batch mixer

Accelerate bulk powder dispersion into liquid

Inline high shear mixers instantly boost batch production without disturbing

existing equipment

Streamline your mixing process

Eliminate floating powders

SLIM Advertisement

SLIM (Solid-Liquid-Injection-Manifold)

SLIM technology is ideal for the rapid introduction of difficult to wet solids. The newest generation of powder injection systems - the Batch or Inline Solid-Liquid Injection Manifold, or “SLIM,” combines the mixing of powders and liquids simultaneously by injecting powders directly into a specially engineered high-shear rotor/stator mixer, where the powder is immediately dispersed into the liquid stream. In most applications, these new solid/liquid injection systems shorten mixing cycles dramatically.

Batch Design |

Inline Design |

Powders like fumed silica, titanium dioxide, gums and thickeners are difficult to wet out. Even with a strong vortex in an open vessel, they resist wetting out, and often float on the surface for hours. Our new SLIM technology enables you to wet out powders almost instantly. The SLIM system sucks solids directly into the high shear rotor-stator where they are immediately wetted out and dispersed into the liquid. |

The rotor/stator generates an intense vacuum and sucks in powders and liquids into the rotor-stator area. A feed tube adjacent to the back of the rotor provides a path to inject solids directly into the stream. The solids are combined and mixed into the flowing stream at the same point, the mixer is capable of handling extraordinarily large volumes of solids without clogging. |

Technical Information

- Typical Production Rates

- SLIM Inline Operating Theory

- Operation and Performance Criteria

- Use of Hose & Wand vs. Hopper

- Pumps & SLIM

- Installation Examples

Trade Articles

As with any other mixer or blender, the process of specifying a powder induction system for your application is best accomplished working closely with your mixer manufacturer, in a testing laboratory. This gives you an opportunity to systematically assess the unit’s efficiency, working with your own ingredients, in a controlled setting. It also allows you to refine your mixing technique – an important step in optimizing the performance of any mixer.

Multi Shaft Mixers

Multi-Shaft Mixers are available in fixed tank and change can designs. They are also offered in dual or triple shaft configurations to match up with your specific process needs.

|

|

The Dual Shaft design includes a conventional high speed disperser and a three-wing anchor agitator. This configuration is ideal for straightforward dispersion and mixing applications. |

The Triple Shaft model extends the operating range of this product line by adding either a high shear rotor-stator mixer, or a second high speed disperser. The addition of a high shear rotor-stator mixer adds the capability of emulsifying and homogenizing products that require higher shear to reduce the size of the particles being mixed. |

Both designs are available in sizes that range from 1 gallon laboratory up to 4000 gallon production models. The change can units are built through 1000 gallons capacity.

All units are available with the following options:

- vacuum construction

- jackets for heating or cooling

- sanitary design

- numerous discharge valve selections

- cover openings to meet your needs

- a range of horsepower selections for the agitators

- scrapers to wipe the vessel walls

- variable speed drives

- control packages, simple & sophisticated

- special coatings

- a range of materials of construction

Use our Mixer Selection Chart to help select a mixer for your specific needs.

Copyright 2019 Charles Ross & Son Company. All rights reserved.

Copyright 2019 Charles Ross & Son Company. All rights reserved.