How It Works

High Speed Dispersion

High Speed Dispersers consist of a driven vertical shaft and a high shear disk type blade. The blade rotates at up to 5000 fpm and creates a radial flow pattern within a stationary mix vessel. The blade creates a vortex that pulls in the contents of the vessel to the blades sharp edges. The blade surfaces then mechanically tear apart solids thereby reducing their size, and at the same time dispersing them among the liquid used as the carrier fluid.

High Speed Dispersers are ideal for dispersions that are up to a maximum of approx. 50,000 centipoise. When used in conjunction with Multi-Shaft Mixers, they can be useful to several hundred thousand centipoise. Most are supplied with air/oil hydraulic lifting mechanisms to enable their use with multiple mixing vessels. Fixed tank designs are available, and both can be supplied for either vacuum or pressure operation.

Dispersers are available from bench top sizes to very large production sizes capable of dispersing several thousand gallons at a time.

PreMax

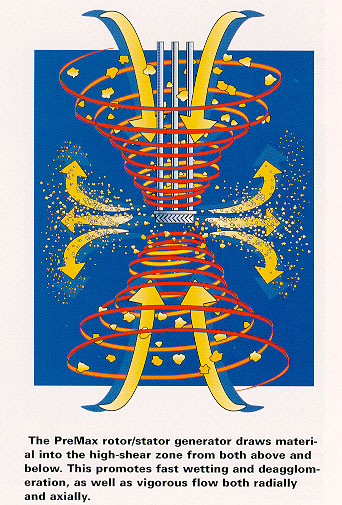

The PreMax is a single stage rotor/stator generator specially contoured to generate high shear and vigorous flow in a batch mixing environment.

The Delta rotor/stator of the PreMax is designed to produce an intense combination of mechanical and cavitational shear, which results in aggressive pigment deaglomeration.

This high shear mixer can reduce the number of passes required through a media mill during pigment dispersion, thereby reducing costs and speeding up production. The PreMax is ideal for flexo, gravure and offset inks, paints, industrial coatings, electronic inks and cosmetics.

Emulsifcation

Our conventional Single and Multi-Stage Rotor/Stator Mixers play important roles in emulsification processes. They are capable of producing simple or complex sub-micron emulsions.

Rotor-stator mixers comprise of a rotor that turns at high speed within a stationary stator. Single stage, dual stage, four stage and complex intermeshing rows of concentric teeth are all available. The basic designs operate at speed of approx. 4000 fpm, whereas the ultra high intensity models, operate at speeds to over 18,000 fpm.

Our high shear rotor-stator mixers are many times more effective than conventional disk type high speed dispersers for low viscosity applications up to approx. 10,000 cps. As viscosity increases the rotor -stator designs are often combined with anchor or turbine agitators to extend their processing range.

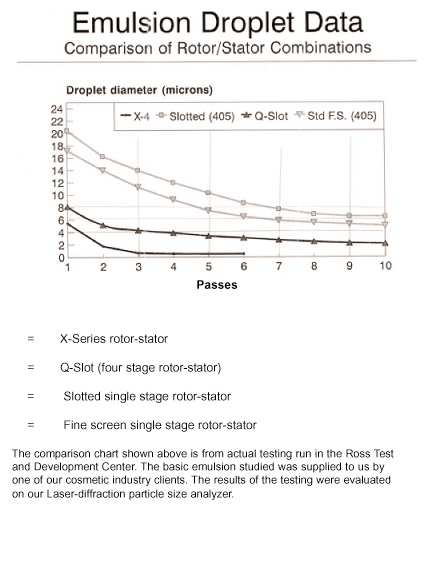

View the Emulsification Droplet Data report we have included (displayed above) to learn more about the capabilities of the various designs that are available. The MegaShear is not shown, however it's capabilities are beyond those of the X-Series model which is included in the graph.

Designs are available for bench-top and production operations. They range from 1/2 hp to over 250 hp and are supplied in batch and inline configurations.